|

Thickness (mm) |

Weight (lb/ft2) |

Weight (g/m2) |

Light Transmission Clear |

Pitch / Depth (mm) |

Pitch / Depth (in) |

Cold Forming min Radius (FT/1") |

U factor (Btu/ft2 h °F) |

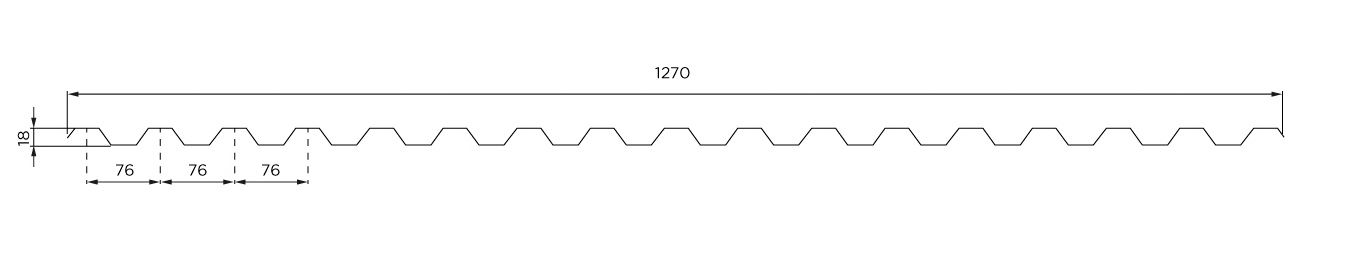

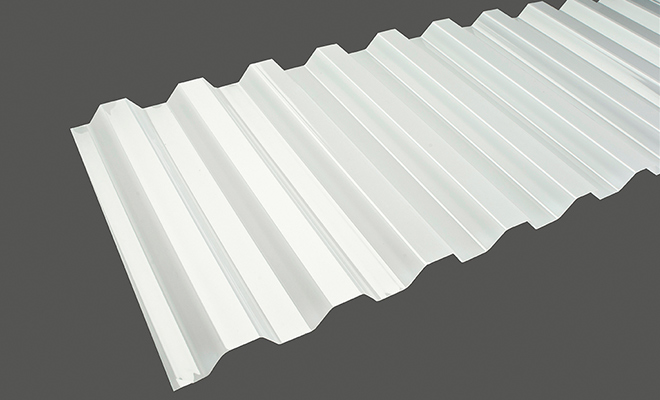

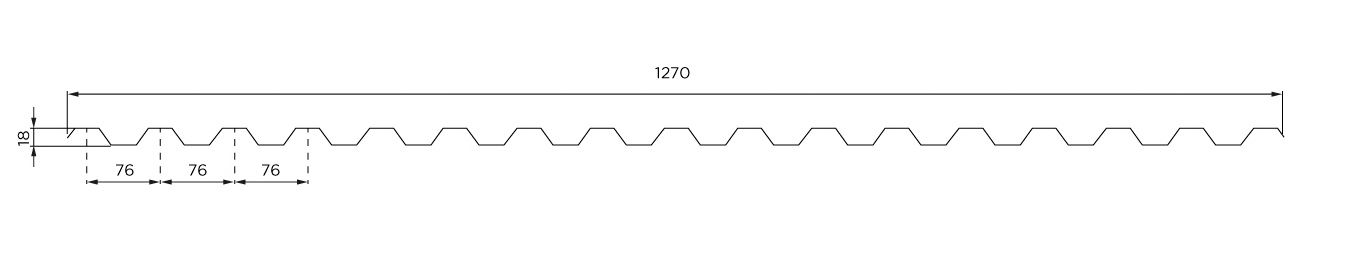

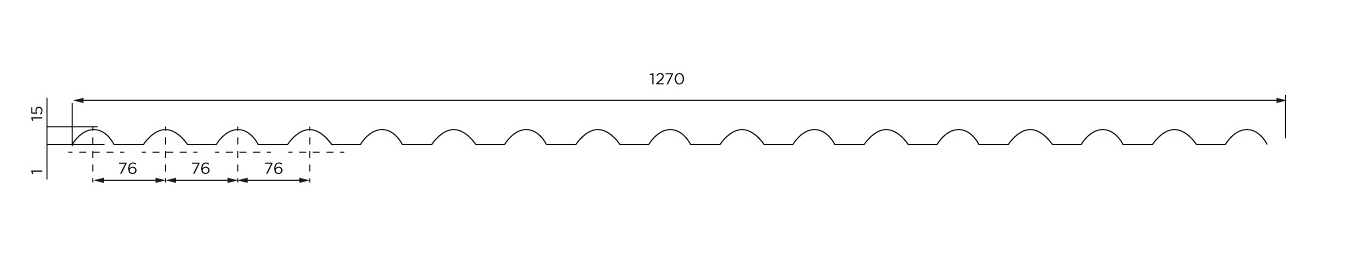

| CORRUGATED STANDARD |

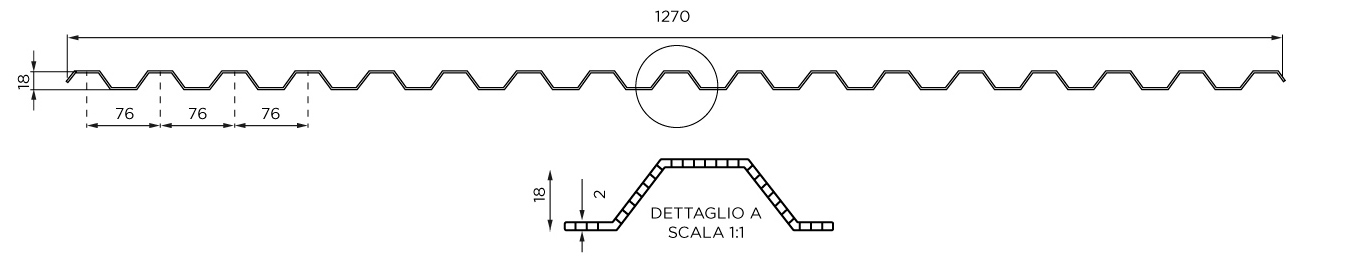

Greca

|

0.8

0.9

1

1.2

|

0.23

0.25

0.27

0.32

|

1130

1200

1300

1560

|

90

90

90

90

|

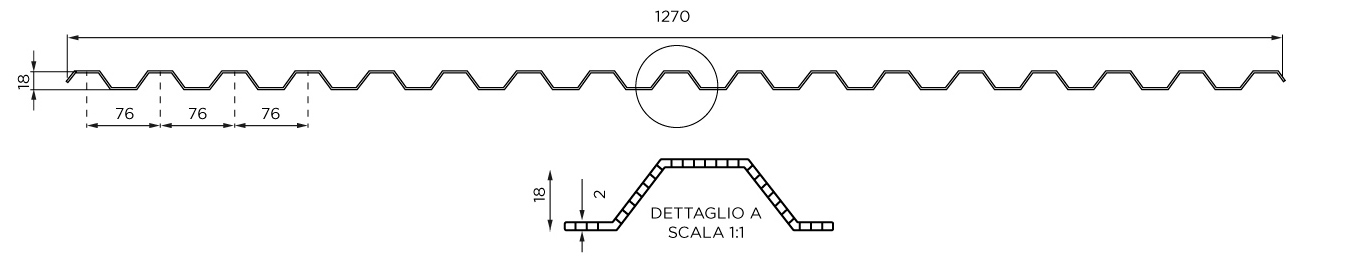

76/18

76/18

76/18

76/18

|

3"/.71"

3"/.71"

3"/.71"

3"/.71"

|

13 1/8'

13 1/8'

13 1/8'

13 1/8'

|

1.14

n/a

n/a

n/a

|

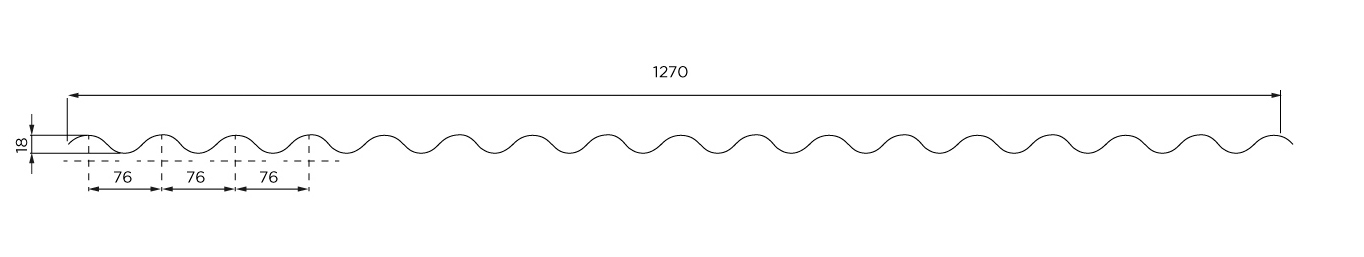

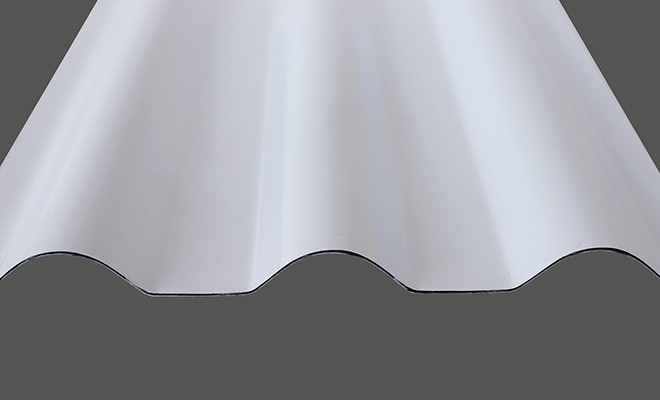

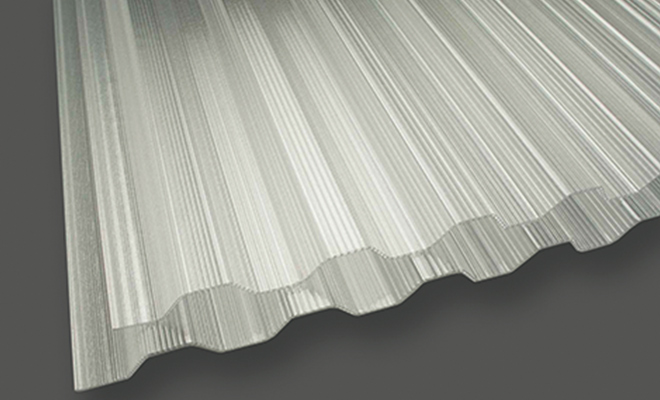

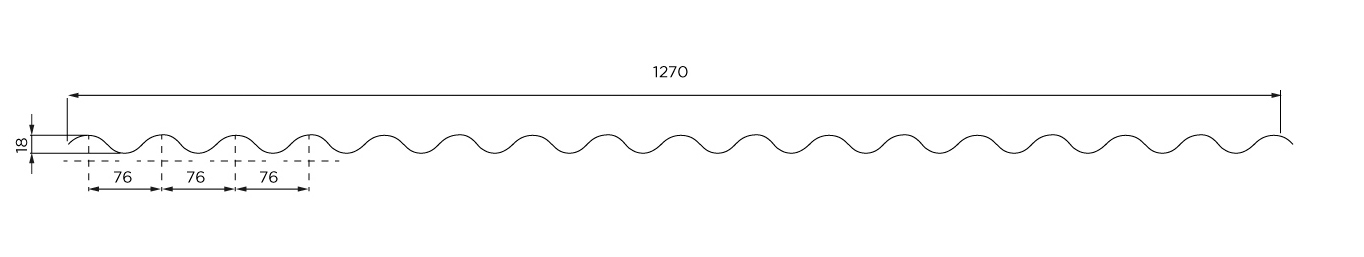

Roma (sine wave)

|

0.8 |

0.22 |

1080 |

90 |

76/18 |

3"/.71" |

13 1/8' |

1.14 |

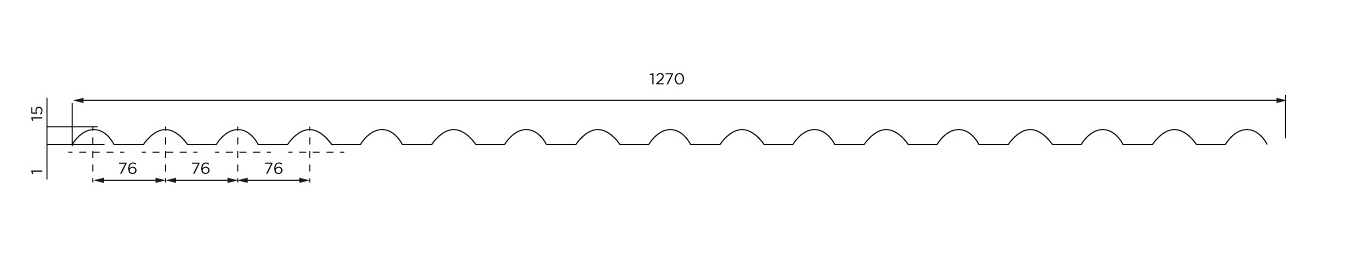

Omega

|

0.8 |

0.23 |

1130 |

90 |

76/15 |

3"/.59" |

13 1/8' |

1.14 |

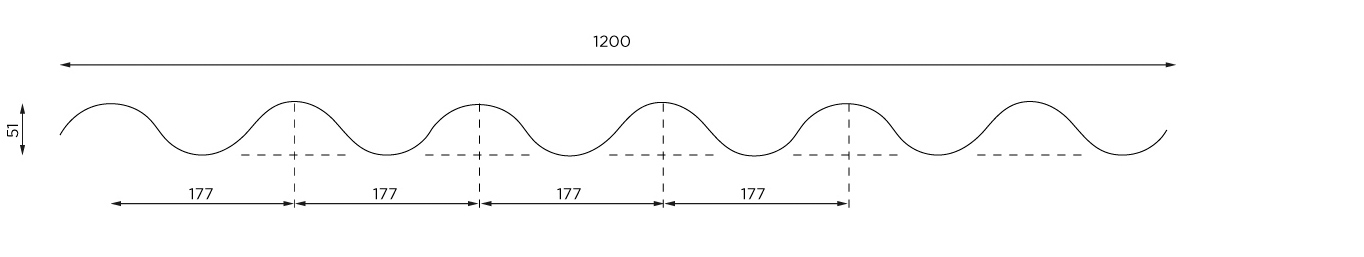

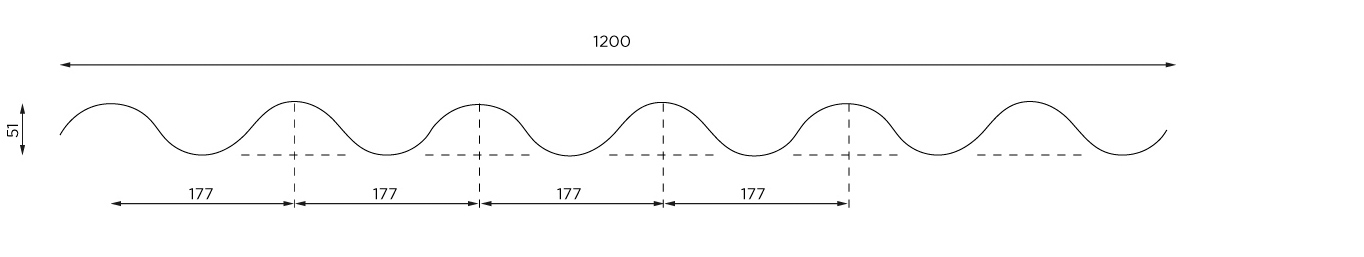

Big Wave

|

0.8 |

0.24 |

1150 |

90 |

177/51 |

7"/2" |

37 3/4' |

1.14 |

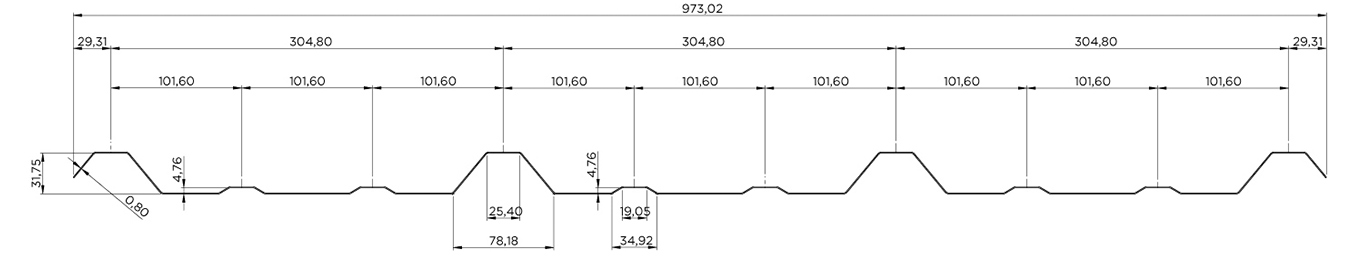

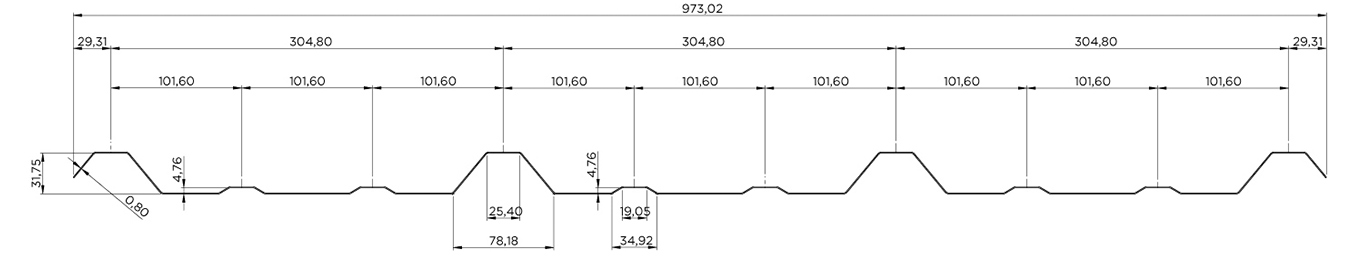

12" R Panel

|

0.8

0.9

1

|

0.26

0.29

0.32

|

1260

1400

1550

|

90

90

90

|

304.8/31.8

304.8/31.8

304.8/31.8

|

12"/1.25"

12"/1.25"

12"/1.25"

|

24 5/8'

24 5/8'

24 5/8"

|

1.14

n/a

n/a

|

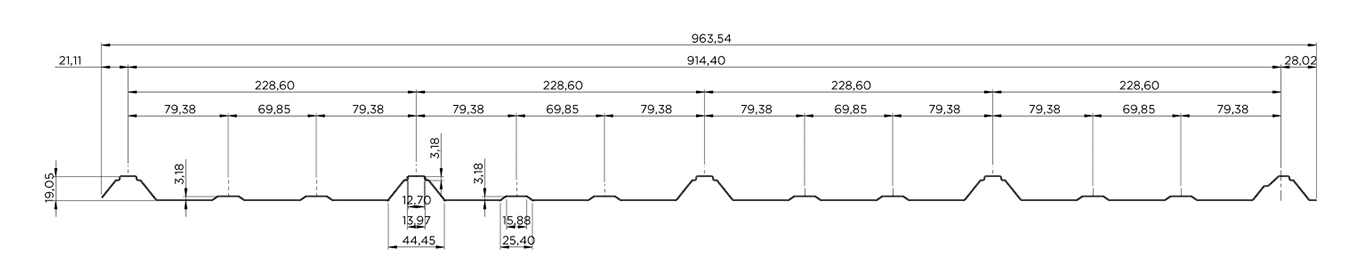

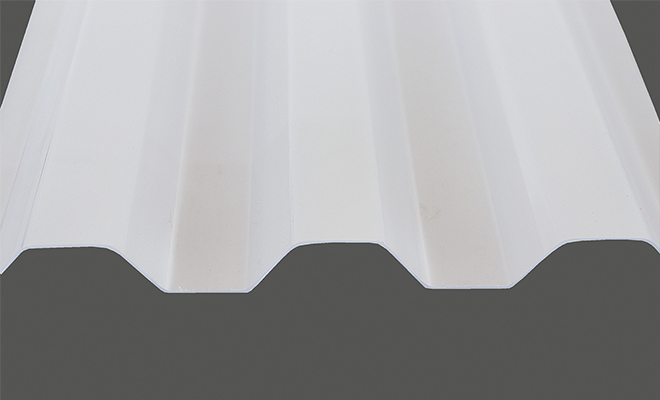

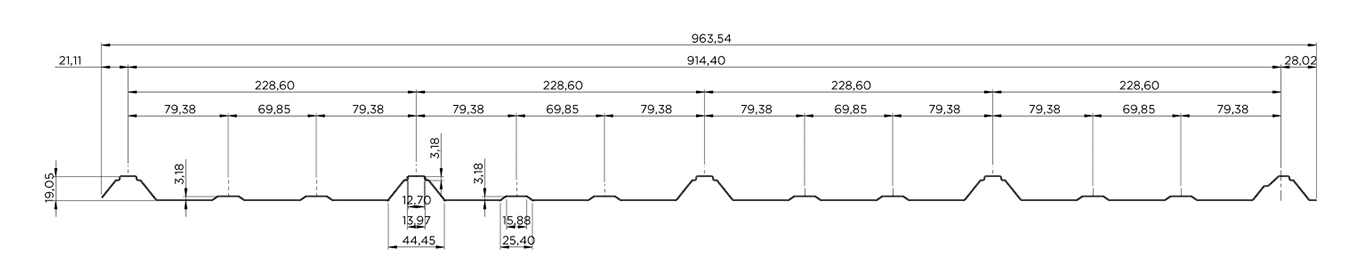

9" On Center

|

0.8

0.9

1

|

0.25

0.28

0.31

|

1210

1360

1510

|

90

90

90

|

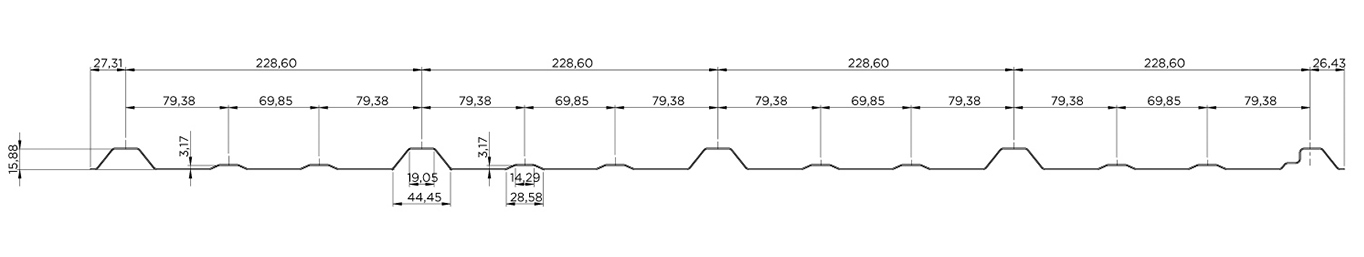

228.6/19.05

228.6/19.05

228.6/19.05

|

9"/.75"

9"/.75"

9"/.75

|

14 3/4'

14 3/4'

14 3/4'

|

1.14

n/a

n/a

|

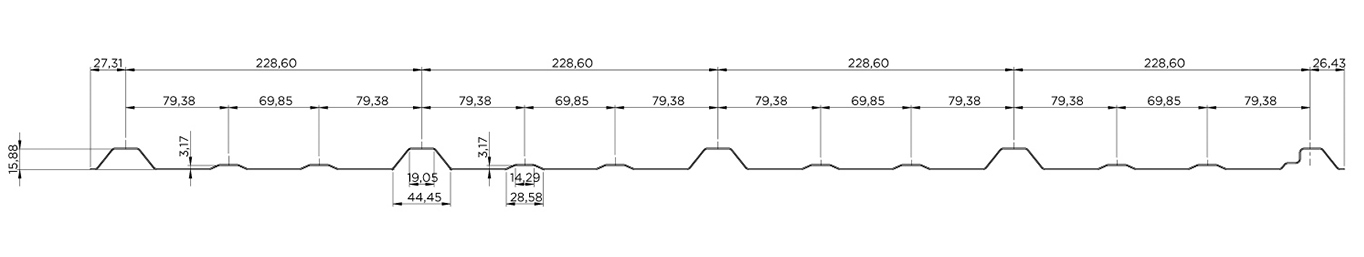

9" Flat

|

0.8

0.9

1

|

0.25

0.28

0.31

|

1210

1360

1510

|

90

90

90

|

228.6/15.88

228.6/15.88

228.6/15.88

|

9"/.62"

9"/.62"

9"/.62

|

14 3/4'

14 3/4'

14 3/4'

|

1.14

n/a

n/a

|

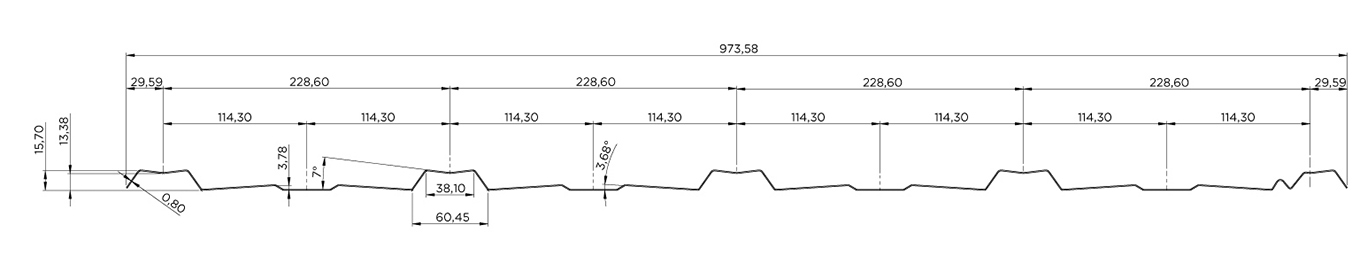

Frontier Rib

|

0.8

0.9

1

|

0.25

0.28

0.31

|

1210

1360

1510

|

90

90

90

|

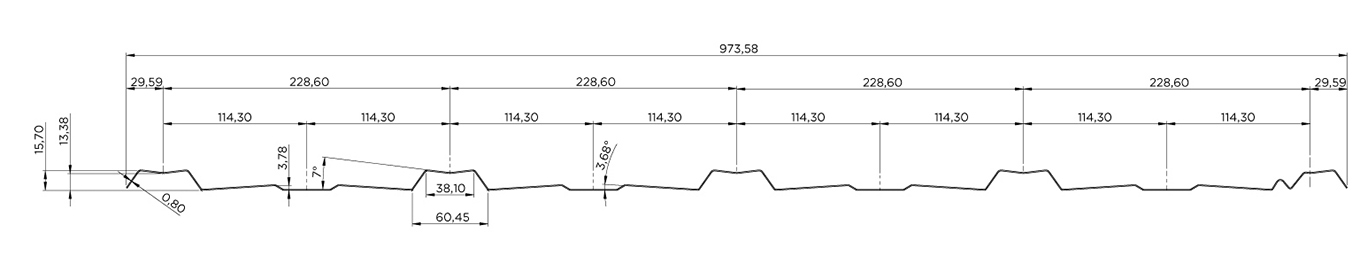

228.6/15.70

228.6/15.70

228.6/15.70

|

9"/.62"

9"/.62"

9"/.62"

|

14 3/4'

14 3/4'

14 3/4'

|

1.14

n/a

n/a

|

| CORRUGATED TWIN WALL |

Greca

|

2 |

0.24 |

1150 |

80 |

76/18 |

3"/.71" |

13 1/8' |

n/a |

NO DRIP

Anti condensate that inhibits the formation of condensation into droplets by reducing surface tension making the condensation run off the sheets into the gutter or drain.

2 UV

Two sided UV Protection for superior resistance against UV rays which helps maintain long term high light transmission.

LIGHT DEPRIVATION CORRUGATED SHEETS

0% Light Transmission corrugated polycarbonate sheets with the option of being in different configurations; black, white/black or white/black/white. This product is available from .9mm to thicker sheets.

FROSTYGLASS

Features a ground glass appearance, providing greater light diffusion. Available finish in the greca corrugated twinwall product.

HIGH DIFFUSION SOFT WHITE

100% light diffusion. Scatters light in greenhouses promoting uniform growth. Produces bigger brighter plants and vegetables. High light transmission, 90%.

| Physical specification |

|---|

| Standard Widths |

26”, 50”, 50.75” |

| Standard Lengths |

Up to 48’ |

| Thicknesses |

0.8mm (0.31”), 0.9mm (0.35”), 1mm (0.39”), 1.2mm (0.47”) |

| Additional widths and thicknesses available. Contact us for more information. |

| Light Transmissions |

| Solid Corrugated |

Clear 90% Opal 60% HD Soft White 90% Bronze 48% Smoke Grey 50% |

| TW Corrugated |

Frostyglass Clear 80% |

| Standard colors |

|

| Special colors available upon request. Contact us. |

| Technical Data | Value |

|---|

| Thermal expansion |

2.1mm for every 3m by 10ºC |

| Thermal conductivity |

0.17W/mºC |

| Vicat softening point |

135ºC (AS 1462) |

| Resistance to Traction |

65 Mpa (AS 1462) |

| Resistance to Impact |

Exceeds 9 joules (AS 4257.6-1994)

Approximately 250 times more than glass. |

| Corrugation Retention |

Without changes for up to 2 hours at 100ºC.

|

|

1. Thermal Expansion – calculate from ambient temperature at time of installation.

2. Impact Resistance – can decline with age.

|

*C=These characteristics have been taken from the CAMPUS plastic database and are based on the international catalogue of databases for plastic according to ISO10350 (Plastics - data acquisition and presentation, comparable only, 1993) NB= No Break

| * | | Test Conditions | Units | Standards | Macrolux Rooflite Resin Values |

|---|

| | Rheological Properties | | | | |

|---|

| C |

Melt volume - Flow Rate |

300ºC; 1.2Kg |

cm3/(10min) |

ISO 1133 |

6 |

| |

Melt Mass - Flow Rate |

300ºC; 1.2Kg |

g/(10min) |

ISO 1133 |

6.5 |

| |

Contraction after parallel/normal molding |

|

% |

b.o ISO 2577 |

0.6-0.8 |

| | Mechanical Properties | | | | |

|---|

| C |

Tensile Modulus |

1mm/min |

MPa |

ISO527 |

2350 |

| C |

Yield Stress |

50mm/min |

MPa |

ISO527 |

65 |

| C |

Yield Strain |

50mm/min |

% |

ISO527-1;2 |

6.3 |

| C |

Nominal tensile strain at break |

50mm/min |

% |

ISO527 |

>50 |

| C |

Stress at break |

50mm/min |

MPa |

ISO527-1;2 |

70 |

| C |

Strain at break |

50mm/min |

% |

b.o ISO527-1;2 |

120 |

| C |

Tensile Creep modulus |

1 Hr |

MPa |

ISO 899-1 |

2200 |

| C |

Tensile Creep modulus |

1000h |

MPa |

ISO 899-1 |

1900 |

| C |

Charpy impact resistance |

23ºC |

KJ/M2 |

ISO 179-1eU |

NB |

| C |

Charpy impact resistance |

-30ºC |

KJ/M2 |

ISO 179-1eU |

NB |

| C |

IZOD Notched impact resistance |

23ºC; 3mm |

KJ/M2 |

b.o ISO 180-4A |

95 |

| C |

IZOD Notched impact resistance |

-30 °C; 3mm |

KJ/M2 |

b.o ISO 180-4A |

16C(P) |

| | Thermal Properties | | | | |

|---|

| C |

Glass transition temperature |

10ºC/min |

ºC |

ISO 11357-1,-2 |

148 |

| C |

Temperature of deflection under load |

1.80 MPa

0.45 MPa |

ºC |

ISO 75-1;2 |

128 140 |

| C |

Vicat Softening temperature |

50N; 50ºC/h |

ºC |

ISO 306 |

148 |

| C |

Co – efficient of linear thermal expansion |

23 a 55ºC |

10-4/K |

ISO 11359-1; -2 |

0.65 |

| C |

Burning behavior UL94

(UL Valoration) |

1.5mm

0.75mm

10mm |

Class |

UL94 |

HB

V-2

V-O(CL) |

| C |

Oxygen index |

Procedure A |

% |

ISO 4589-2 |

27 |

| |

Glow Wire Test (GWFI) |

1.5mm

2.0mm

3.0mm |

ºC |

IEC 695-2-12 |

850

850

930 |

| | Electrical Properties | | | | |

|---|

| C |

Relative permittivity |

100Hz |

|

IEC 250 |

3.1 |

| C |

Relative permittivity |

1MHz |

|

IEC 250 |

3.0 |

| C |

Dissipation factor |

100Hz |

10-4 |

IEC 60250 |

5 |

| C |

Dissipation factor |

1MHz |

10-4 |

IEC 60250 |

95 |

| C |

Volume resistivity |

|

0hm.m |

IEC 60093 |

1E14 |

| C |

Surface resistivity |

|

0hm |

IEC 60093 |

1E16 |

| C |

Electrical strength |

1mm |

kV/mm |

IEC 60243-1 |

34 |

| C |

Comparative tracking index (CTI) |

Solution A |

Rating |

IEC 112 |

250 |

| | Other Properties | | | | |

|---|

| C |

Water Absorption (saturation value) |

Water at 23ºC |

% |

ISO 62 |

0.30 |

| C |

Water Absorption (equilibrium value) |

23ºC / 50% r.h |

% |

ISO 62 |

0.12 |

| C |

Density |

|

Kg/M3 |

ISO 1183-1 |

1200 |

| C |

Fiberglass content |

|

% |

ISO 3451-1 |

- |

| | Specific properties of the material | | | | |

|---|

| C |

Viscocity number |

|

cm3/g |

ISO 1628-1 |

64 |

| |

Refraction index |

Procedure A |

|

ISO 489 |

1.587 |

| | % of Diffusion Factory Light Transmission (DFLT) RET.WIO14 | | | | |

|---|

| |

|

Clear |

White |

Bronze |

Smoke Grey |

| |

% of Light Transmission (DFLT) |

85 |

62 |

48 |

27 |